In 1986, aged 19, I somehow won the logo competition for the Sculptors’ Association of Alberta, in Canada, of which I was also a founding member. I had put the letters “SAA” on three sides of a 5x5x5 cube, going with strict Euclidean geometry as was my wont as a budding logo designer. Problem was, on those three cube faces (which share a vertex), the result had an “Escher twist” in it, recognized by the Association’s president, ironically making it IMPOSSIBLE to make this thing in three dimensions, the very space in which all sculpture lives. In spite of this, my logo was accepted and has been used ever since, an early coup for me.

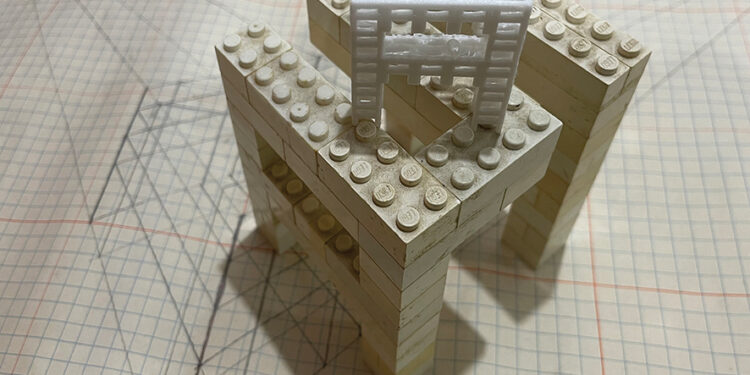

20 years after making that design, in 2006, I was at the house of friends with children in Canada and, seeing a box of Lego parts, asked if I might tinker. Using all white pieces, I succeeded in slightly revamping the SAA logo: now its two Ss are on opposite sides, with the A still on top. This means that it no longer has the dimensional twist making it impossible in 3D. Also, it now has 180-degree rotational symmetry on one axis, a further visual bonus in my aesthetics. I still have this promo-logo in my collection of bits and pieces. Ideally, it’s made of 39 smaller cubes in the original 5x5x5 cube space. Nicely, there does exist a flatter version of it too, which one can cut from a stiff piece of paper (think: business card) and assemble with only two folds into 3D.

In short… I couldn’t get the Association to accept the new logo (there is a long story, but never mind).

Well, I still have the design, and copyright over it. So, realizing that 3D printing in various media has arrived in Georgia, I asked and was directed to a place which does it, in the Techno Park at the end of Innovation Street in Oqrokana, Mtatsminda, overlooking Tbilisi. Their material is plastics, and I found myself asking for help to first render my design on a computer’s 3D program, and then to print it (I had dabbled in such programs myself, and decided that yes, I can learn them, but the curve will be quite steep, and my patience currently short. Something for the future). This was my first ever venture into a 3D printing lab, and I was fascinated.

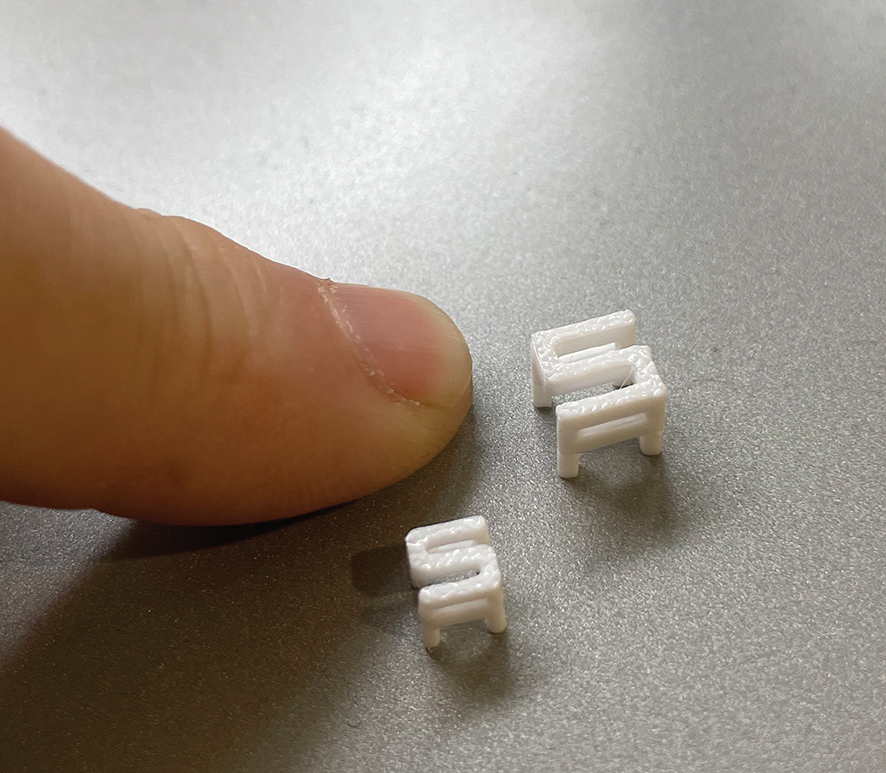

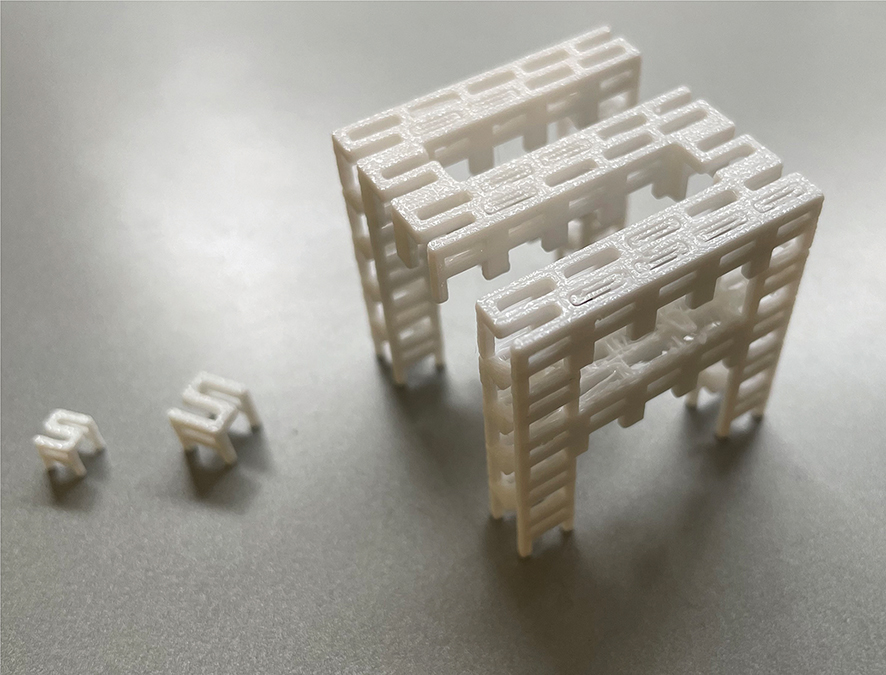

No problem with rendering help, once I made myself understood! We did a tiny model, 5 mm on a side, first, then scaled this slightly up to 7 mm. The reason for this is that I have dreamed of a FRACTAL version of the logo too. This entails putting together 39 copies of that 7 mm logo, to make a 2nd-iteration one, 35 mm on a side, and then even another one, the largest size the machine can make, with 39 copies of the 2nd-iteration model, measuring 175 mm on a side.

The 2nd iteration model took nearly an hour to print, due to its great intricacies, typical of fractals. And then, after numerous program and computer crashes while rendering the 3rd-iteration model onscreen, the time estimate for printing this 3rd-iteration monster came back. More than two days of continuous printing. Fractals can get ridiculously detailed in very little time.

3D printing (joined by 3D scanning) is a field which is growing very fast, too, with all sorts of different materials and methods, some additive, some subtractive. Along with various plastics, there are metals, ceramics, stone, wood and more. It partly depends on your needs and budget. But it’s a very exciting industry, still in its youth, and every few months bringing new innovations and improvements.

The printing lab on Mtastminda doesn’t leave its machines running overnight unsupervised, as there is a fire risk from using melted plastic. And I suspect that a print over such a long time is more than they’ve ever done before. But they’ve offered to make it in several sections, over a week or so, which I could then carefully glue together. We’ll see if I can do this. In the meantime, I’m dazzled by my introduction to 3D printing, typically wanting to fly before I can walk, and will end up with a fractal version of my logo, whether the SAA ever goes with it or not. It’s fun, and a learning process, if nothing else.

Merry Christmas and a Happy New Year!

Blog by Tony Hanmer

Tony Hanmer has lived in Georgia since 1999, in Svaneti since 2007, and been a weekly writer and photographer for GT since early 2011. He runs the “Svaneti Renaissance” Facebook group, now with over 2000 members, at www.facebook.com/groups/SvanetiRenaissance/

He and his wife also run their own guest house in Etseri: www.facebook.com/hanmer.house.svaneti